¿Qué pasó en la cadena de suministro durante 2021?

The growth of world trade and the increase in demand for goods gave rise to a series of challenges in the supply chain that companies had to face in 2021.

Therefore, to maintain a successful and profitable business, it is important for manufacturers to be aware of the challenges that could continue to affect their supply chain through 2022. By being aware of potential obstacles, companies can develop contingency plans and take action. to mitigate any potential disruption. This article examines the key major challenges that could affect businesses in the coming year.

Impact of the pandemic on the manufacturing industry

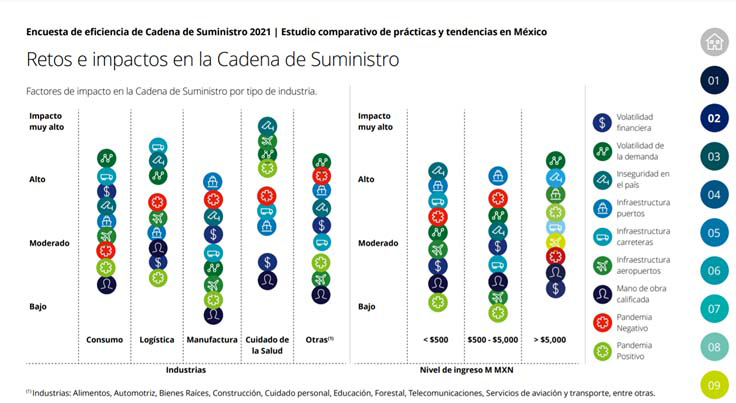

Un estudio realizado por study carried out by Soy Logístico and analyzed by Deloitte revela el impacto significativo que la pandemia ha tenido en empresas de todos los tamaños, incluyendo aquellas en la fabricación de automóviles, electrodomésticos y equipos de tecnología. Este impacto ha generado tanto consecuencias negativas como positivas. En el lado negativo, la pandemia ha causado perturbaciones operativas y cierres de puertos e industrias. En el lado positivo, ha habido una reactivación y un apetito por nuevos productos por parte de los consumidores. Sin embargo, estos factores se han encadenado y ahora se reflejan en escasez, mayores costos y precios, inflación y una amenaza para la recuperación económica.

En este contexto, es importante destacar la relevancia de contar con soluciones logísticas eficientes y efectivas que permitan mitigar estos impactos. Algunas de estas soluciones incluyen el uso de tarimas, empaques, embalajes y paletas de madera que cumplan con los requisitos de tratamiento térmico y certificación de madera sostenible. Además, es importante considerar el diseño de embalaje y sistemas de fijación adecuados para proteger la carga durante el transporte, especialmente en el caso de productos de carga pesada o destinados a la exportación. También es fundamental contar con opciones de almacenamiento de productos y soluciones de embalaje industrial que garanticen la seguridad del transporte y la protección de los productos. En resumen, la cadena de suministro necesita de soluciones eficientes y sostenibles para adaptarse a los desafíos presentes y futuros, y la madera puede ser una gran aliada en este proceso.

Non-compliance of suppliers in the supply chain

The scarcity of certain inputs for production has caused raw materials, such as wood, to rise in price, since 83% of the wood is imported and 17% of national production. This material is used for the manufacture of furniture or packaging for a variety of other products, as well as for platforms or pallets used in the transport of goods and warehouses where stocks are kept.

This problem caused production stops in 2021 and increased costs for many companies, which generated delays in the entire logistics process.

As a manufacturing company, it is important that you know that these issues can continue to occur, however and fortunately, there are ways to overcome this obstacle, one of them is, diversifying your portfolio of suppliers, in this way if any of your suppliers lacks raw material, you can rely on your alternate supplier.

Financial Volatility

Financial volatility in Mexico's manufacturing industry is a major problem. Although Mexico has become one of the most promising economies in Latin America, it still faces significant challenges related to economic instability and financial risk.

In October 2021, the industrial sector only grew 1.6% per year in our country, when a year ago it fell 3.3%. This is due, to a large extent, to the fact that transportation equipment registered a decline of 12.4% per year, affecting the manufacturing segment, on which 58% of industrial GDP weighs.

Despite some challenges, global trade has had a net positive impact on the world. As we head into 2022, it's important to know that supply chains are changing and you'll need to plan accordingly. If you want help to optimize your supply chain through packaging and wooden pallets, get in contact with us!